Interview with the President of the Biodegradable Materials Business

Q1. Why are you working on biodegradable materials?

The serious plastic waste problem in China is an urgent issue

Rachel Carson's book "Silent Spring," published in 1962, conveys the dangers of chemicals such as DDT and other pesticides by explaining an event when birds stopped singing in spring. This book had a major impact on the chemical industry. It fundamentally overturned the idea of chemical safety and as a result, some typical chemical products, including DDT, which had been used as a mainstream pesticide until then, were regulated. And now, I think that the world's environmental and waste problems are in exactly the same situation as at that time.

The problem of plastic waste pollution is not so serious in Japan, since the plastic recycling model was established at an early stage and the recycling rate has reached over 80%. On the other hand, in China's vast land, it is difficult to completely dispose of waste, so a large amount of plastic waste is buried in the soil and flows into rivers and lakes, causing serious environmental pollution problems. According to the 2018 China Marine Survey, the amount of plastic particles at the entrance to the Yangtze River has reached the world's highest level. In addition, other river surveys have shown that it is at least 30 times higher than the average for developed countries. In some cases, a large amount of fine plastic particles has been detected in cotton produced from long-fiber cotton in Xinjiang, which is a famous cotton producing area, which is difficult to remove and the commercial value has plummeted.

Freshwater fish are a major source of protein for Chinese people, and the government is paying close attention to the potential health hazards of eating fish that have eaten plastic particles, which have already been scientifically proven. The National Development and Reform Commission of China announced the "Opinions on Further Strengthening the Control of Plastic Pollution" on January 16, 2020. A roadmap was announced to stop the progress of pollution, which calls for the prohibition and regulation of the production, sale and use of plastic products in some regions and fields by 2020; significant reduction of consumption of disposable plastic products by 2022: and the establishment of a plastic recycling system by 2025. This policy has already begun to be enforced in some areas such as Hainan Province in China in March. In addition, China plans to scale its measures to stimulate the economy following coronavirus to several trillion yen. With restrictions placed on the largest exporters due to the US-China trade conflict, I think that these funds may be more likely to move towards new energy and new materials, as additional investment in existing industries could trigger further domestic surplus.

Q2. Biomass plastic seems to be attracting more attention than biodegradable plastic in Japan. Why did you pay attention to biodegradability?

Problems with biomass plastics

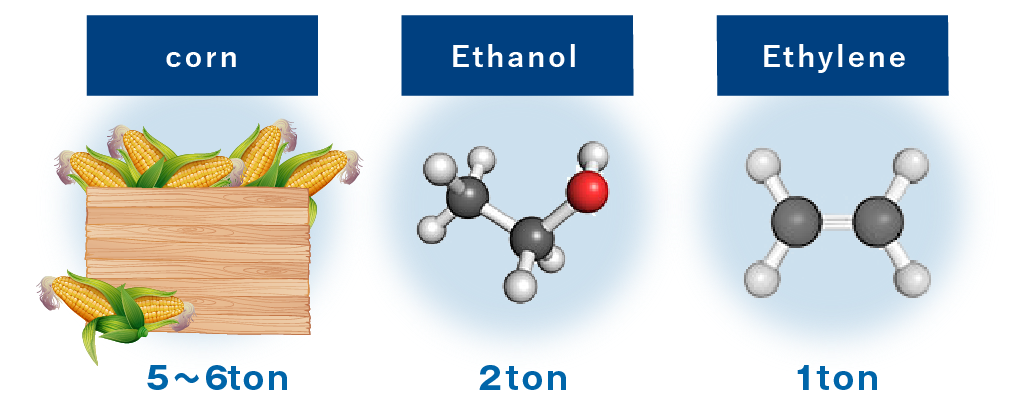

The raw materials for bioplastics are mainly agricultural products such as corn. A large amount of agricultural products are consumed in production, which may further increase the burden on the global food shortage problem. Generally, the production of 1 ton of ethylene requires 1.6 tons of ethanol, and the production of 1 ton of ethanol requires 3 tons of corn. Therefore, when 1 ton of ethylene is produced by the bio method, about 5 tons of corn is consumed. Currently, 500 million tons of synthetic materials consisting of plastics and fibers are produced in the world annually, and 400 million tons are plastics. It is said that disposable plastic and packaging materials account for about 150 million tons, 36% of the total. There is a possibility that these will flow out to the oceans and rivers, and if we try to replace all of them with "bio", it has been calculated that more than 1 billion people will need food. I think it is doubtful that using the food of 1 billion people to make disposable plastics is really environmentally friendly. That is why I believe that it is necessary to manufacture biodegradable materials using chemical synthesis in order to seriously tackle the microplastic and marine problems.

Q3. Is there a connection to the C1 chemicals that HighChem has been working on for many years?

Mass-producing cheaper and more earth-friendly biodegradable plastics using C1 chemicals

In China, we believe that C1 chemicals, which we have been working on for many years, will play a major role in producing biodegradable plastics using chemical synthesis methods. It will be possible to mass produce biodegradable materials by utilizing C1 chemicals that can be produced from raw materials that are abundant in China such as coal and natural gas. Since the raw materials for making lactones are, for example, CO and EO (ethylene oxide), they can be obtained in large quantities at, for example, our C1 chemical complex based in Yulin. I also believe that applying C1 chemicals can simplify manufacturing and reduce costs. Furthermore, the use of C1 chemicals in the production of polymer materials is expected to have the effect of reducing CO2 emissions compared to manufacturing technology that uses petroleum as a raw material. The synthetic method using C1 chemicals has the characteristic that the carbon utilization efficiency is much higher than that of the petroleum method. Therefore, it is possible to manufacture biodegradable plastics in larger quantities, at lower cost, and in a way that emits less CO2.

Q4. What are the particular things that HighChem can do in regard to biodegradable materials?

Develop into a total solutions company for biodegradable materials and solve the world's waste problems

If China puts a huge amount of money into biodegradable materials, the production capacity of biodegradable raw materials will increase dramatically. However, there are still technical issues to be solved for their widespread use. As materials, even if they are mass produced, they cannot become widely used unless their colors and shapes are adjusted so that they can actually enter into everyday life without causing inconvenience to consumers. And I think that material manufacturing is all about craftsmanship and quality recipes that transcend process flows that "imprecisely" mix, push, and stretch materials such as polymerization, processing, and molding And this is exactly what the Japanese are best at.

I am convinced that it will be Japanese material technology that will solve the world's marine waste and microplastic problems. I hope that HighChem will become a bridge between the emerging Chinese biodegradable raw material suppliers and Japanese material technology, become a total solutions company for biodegradable materials, and tackle the global environmental and microplastics problems.

Click here for inquiries about this product

Biodegradable Materials Project Office Person in charge: Taka TEL: +81-3-5251-8580