SEG® Licensing Business

HighChem, in collaboration with Ube Industries, Ltd., is developing a SEG® technology licensing business for energy-related companies in China.

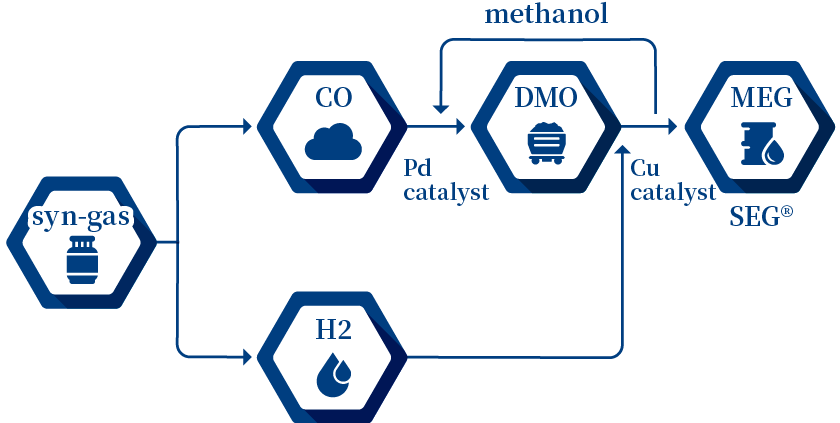

What is SEG® technology?

SEG® technology uses synthetic gas as a raw material to produce ethylene glycol (a type of polyester manufacturing raw material) derived from non-petroleum sources. A wide range of raw materials such as coal, natural gas, and industrial exhaust gas can be used as the raw material. We are also conducting research and development on the production of ethylene glycol using biomass and CO₂ as raw materials.

Low Environmental Impact and Highly Economical Process

Conventionally, ethylene glycol is produced by the "ethylene method" using petroleum as a raw material, but the carbon atom utilization rate is as low as 70%, with 25% being emitted as CO₂. However, the SEG® method achieves a carbon atom utilization rate of 95%, making it a process with low environmental impact and high economic efficiency. Therefore, half of the ethylene glycol produced in China has changed to SEG® method.

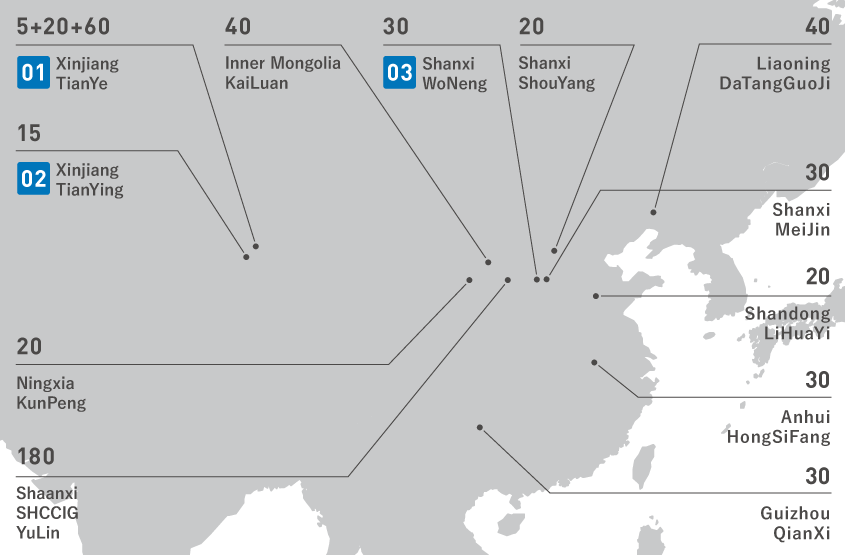

Industrialization track record

CO₂ reduction effect of about 1.25 million tons per year (Unit: ten thousand ton)

HighChem has signed a total of 23 license agreements for SEG® technology, with a total production capacity of approximately 9.4 million tons per year. More than 1 million tons of this is in commercial operation. In addition to energy sources such as coal and natural gas, off-gas emitted during the production of carbide and steel can also be used. Within the total amount produced under license, 750,000tons uses this off-gas as the raw material, and if all of these projects go into operation, it will reduce CO₂ emissions by about 1.25 million tons per year (as of August 2020).

Global expansion

Up to now, HighChem has been developing its licensing business mainly in China. Based on this know-how, we plan to expand globally in the future. We will develop the SEG® business in countries such as Turkmenistan, Indonesia, Middle Eastern countries, Russia, and Canada, which have abundant resources such as natural gas. We are actively developing the business, with the aim of further expanding around the world.