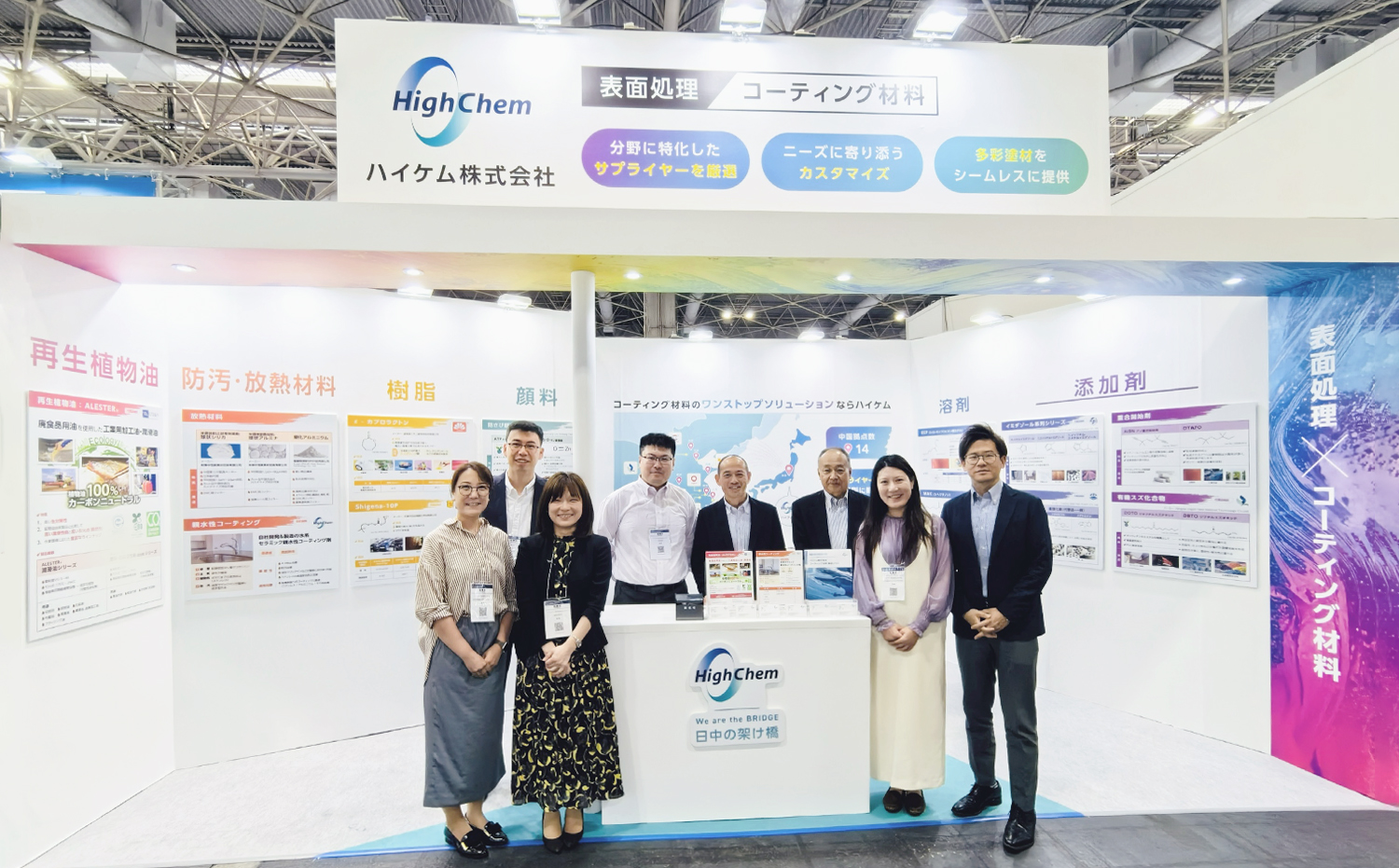

Exhibiting at High-Performance Materials Week: Coating & Painting Equipment Expo!

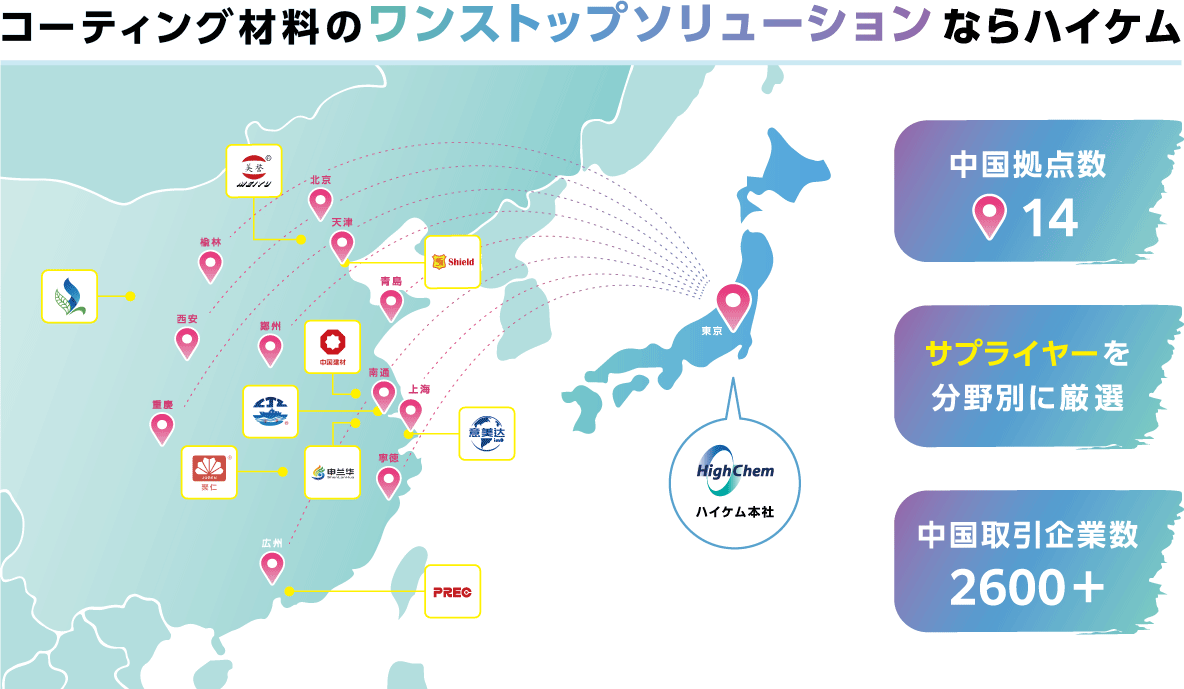

At the exhibition, under the theme of a “One-Stop Solution for Coating Materials,” HighChem introduced products from carefully selected Chinese manufacturers across a wide range of categories including additives, solvents, pigments, resins, and thermal management materials.

In this feature, we highlight the popular "Anti-Fouling and Thermal Management Materials" section of the exhibition, introducing the “Hydrophilic Coating,” “Spherical Silica,” and “Spherical Alumina,” as explained by our product managers.

Heat-Resistant and Easy-to-Clean: Hydrophilic Coating

One of the highlights at the HighChem booth was its proprietary product: a water-based ceramic hydrophilic coating. We interviewed Mr. Inutake, Division Director, and Mr. Toki, the product manager, to learn why it attracted so much attention.

── What is a hydrophilic coating?

Our hydrophilic coating is a silica-based coating that, when applied to surfaces such as stainless steel or aluminum, transforms the metal surface to a glass-like finish.

①Excellent Anti-Fouling Properties

By creating a glass-like surface, the hydrophilic property is enhanced, making it easier to remove dirt. For instance, even if a surface treated with our coating is marked with an oil-based pen, the marks can be wiped off easily with just water.

②High Heat Resistance

The coating works by chemically bonding ceramic powders such as silica to the metal surface through heating. Because ceramics are highly heat-resistant, applying this coating enhances the heat tolerance of the metal. For example, stainless steel coated with this product can withstand temperatures up to around 400°C while preventing discoloration.

── What are the intended applications?

Because of its heat resistance and ease of cleaning, the coating is ideally suited for kitchens and wet areas. Applying it to sinks or stove hoods could help reduce cleaning frequency.

We also believe that applying this coating to the metal surfaces of home appliances and cookware could enable manufacturers to market them as "easy-to-clean appliances" or "pots with easy stain removal."

Additionally, I see potential for this product to serve as an alternative to the widely used anodizing treatment currently applied to aluminum surfaces.

While anodizing enhances aluminum’s corrosion and abrasion resistance through surface treatment, our hydrophilic coating could offer a different texture and set of functionalities as a potential replacement.

HighChem’s Selected Products: Exclusive Distributor in Japan for “Spherical Silica” and “Spherical Alumina”

At the exhibition, HighChem introduced several products from Chinese manufacturers with whom it holds exclusive distribution rights in Japan. Among the highlights were “spherical silica” and “spherical alumina,” widely used as fillers in semiconductor encapsulation materials. HighChem has signed an exclusive distributor agreement with China’s third-largest manufacturer in this category. We asked our product team to explain more.

── We heard that thermal management materials like spherical silica and alumina drew considerable attention at the exhibition. Can you tell us more about these products?

Spherical silica is used as a filler in epoxy molding compounds (EMC) for semiconductor device packaging and similar applications.

Typically, EMCs use high-performance epoxy resins, but due to their high cost, silica—known for its excellent insulation and dielectric properties—is added as a cost-effective filler.

By shaping the silica into spherical form, the filling efficiency into resins is significantly improved—hence the name “spherical silica.”

── I see. So what about spherical alumina?

Alumina is highly thermally conductive and cost-effective, making it ideal for use as a filler in thermal interface materials such as heat dissipation sheets when shaped into spherical form.

It is also used as a filler in EMCs for AI and power semiconductors. Although it is more expensive than spherical silica, it is preferred in applications where high thermal conductivity is critical.