自社触媒工場

2011年に中国・南通市に触媒工場を開設し、SEG®触媒や環境触媒などの金属固体触媒領域におけるリーディングカンパニーとして世界をけん引しています。

南通触媒工場の概要

設立 |

2011年8月 |

従業員数 |

約170名 |

延床面積 |

40,500㎡ |

住所 |

中国江蘇省南通市経済技術開発区 通順路6号 |

主な製品

|

|

|

|

|---|---|---|---|

SEG®-DMO合成触媒 1,500㌧/年 |

SEG®-EG合成触媒 1,500㌧/年 |

DMC合成触媒 500㌧/年 |

SCR低温脱硝触媒 1,000㌧/年 |

・OEM製造受託など

触媒工場紹介ムービー

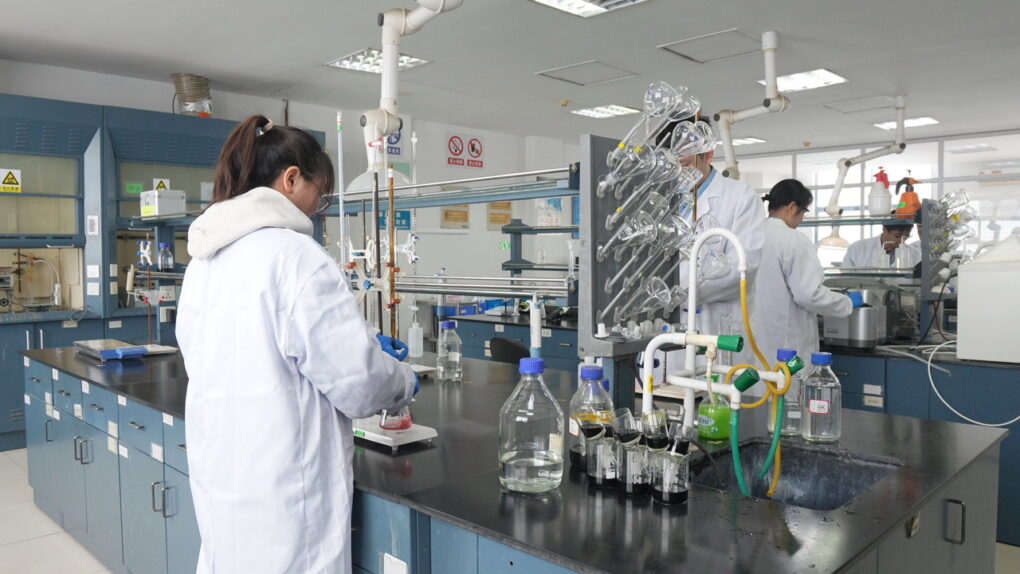

研究開発体制

日中に研究所において約60名の研究員が在籍し、ラボから社会実装までの開発を担い、触媒領域の最先端技術を切り拓いています。

東京研究所

既存触媒の改善・改良をはじめ、新技術の開発や基礎研究を担います

|

|

|

|---|

南通研究所

南通触媒工場と併設されたメリットを生かし、スケールアップ開発やパイロットプラントの検討など、社会実装へ向けた研究開発を担っています

|

|

|

|---|

上海研究所

新規触媒の社会実装において、全体プロセスの設計からエンジニアリング支援までを担う重要拠点です

|

|

|

|---|

グリーン触媒の量産化・社会実装へ向けた取り組み

ハイケムは、新規触媒を短期間で商業化につなげた実績を評価され、グリーン触媒の量産化・社会実装に向けた複数の国家プロジェクトへの参画や大学との共同開発を行っています。

ハイケムの研究開発体制紹介ムービー

ハイケムが参画する触媒の社会実装プロジェクト

・NEDOのCO2からパラキシレンを製造するプロジェクト

世界初のCO2由来パラキシレン製造プロジェクト開発 キーパーソン座談会 /article/ihc09/・NEDOの規格外ココナッツから持続可能な航空燃料(SAF)の製造に参画

・JICA(国際協力機構)と中国の科学技術部による日中共同プロジェクトにハイケムと中国の大手金属供給メーカー貴研とともに、CO2と水素からギ酸を合成する技術開発及びギ酸から水素を取り出す技術開発。

日中共同プロジェクトで新たな触媒技術を開発 /article/project02/

・北海道大学の触媒科学研究所とバイオマス由来の資源化技術の共同研究を行うラボ

北海道大学と共同ラボを設立!植物由来で未来のペットボトルや繊維の量産化を目指す /article/event_hxh/

カーボンデザイン https://highchem.co.jp/business/carbon-design/