The University of Toyama, Chiyoda Corporation, NITTETSU engineering Corporation, Nippon Steel Corporation, HighChem Company Limited, and Mitsubishi Corporation (hereinafter referred to as "Joint Researchers") jointly applied for and were selected by NEDO (*1) for "carbon recycling- Development of Next Generation Thermal Power Generation Technology / Development of Technology for CO2 Emission Reduction and Effective Utilization / Development of Technology for CO2 Use to Chemicals We are pleased to announce that our application has been accepted.

1. Outline

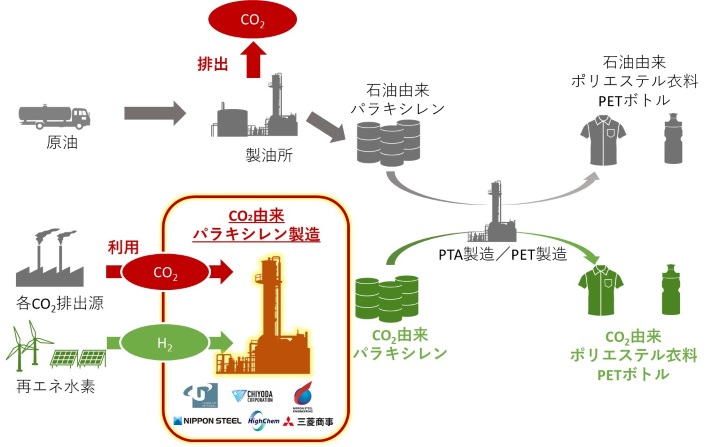

The reduction of CO2 emissions from thermal power generation, etc. is important as a measure against climate change, and the development of "carbon recycling technology" to capture and effectively use CO2 as a resource is required. The "carbon recycling Technology Roadmap" formulated by the Ministry of Economy, Trade and Industry (METI) in June 2019 shows the policy to reduce CO2 emissions into the atmosphere through the use of CO2 as a material or fuel.

Against this backdrop, NEDO has launched a project to develop the world's most advanced technology for the production of paraxylene (*2) from CO2 as a raw material for Chemicals, which aims to replace the existing fossil fuel-derived Chemicals. The joint researchers have been selected as the contractor for this technology development project. Para-xylene is a compound that is processed into polyester fiber, plastic bottle resin, etc. via purified terephthalic acid (PTA) (*3) and is an extremely important basis Chemicals in industry. Due to its composition, carbon recycling technology to produce Chemicals has the advantage of fixing CO2 while reducing the amount of hydrogen feedstock used, making it a theme with great potential from both economic and environmental perspectives. The global demand for paraxylene is about 49 million tons/year, and if all of the current global demand for paraxylene were switched to CO2 feedstock, the amount of CO2 fixed would amount to 160 million tons/year.

In this project, we will improve an innovative catalyst to produce paraxylene from CO2, develop mass production technology and process development, as well as conduct a feasibility study including overall economics and CO2 reduction effects, aiming to create a path to the demonstration stage.

2. Business

Project name: Technological development of paraxylene production using CO2 as feedstock

R&D items:

(1) Catalyst development (performance improvement of new catalysts, extension of catalyst life, etc.)

2) Catalyst scale-up development (mass synthesis of catalyst components, molding for industrial catalysts, etc.)

(3) Process development (optimization of process flow, optimization of operating conditions, etc.)

(4) Feasibility study (evaluation of economic efficiency and CO2 reduction effect according to reaction path, market research)

Contractor:

University of Toyama (R&D Item 1)

Chiyoda Corporation (R&D item 3)

NITTETSU engineering Corporation (R&D item 3)

Nippon Steel Corporation (R&D items 1 and 3)

HighChem Company Limited (R&D items 1 and 2)

Mitsubishi Corporation (R&D item 4)

Project period: FY2020 - FY2023

Budget: 1.99 billion yen

(*1) NEDO: New Energy and Industrial Technology Development Organization

(*2) Paraxylene: An isomer of xylene, which is an aromatic hydrocarbon. It is used as a raw material for terephthalic acid, which is a raw material for polyester fiber and plastic bottle resin. In the chemical formula, it is represented by C8H10.

(*3) High-purity terephthalic acid (PTA): A type of aromatic carboxylic acid, PTA is obtained by oxidizing paraxylene (chemical formula: C8H6O4). Polyethylene terephthalate (PET) is obtained by reacting PTA with ethylene glycol, and PET is used as a raw material for polyester fibers and plastic bottle resin.

Contact information regarding this matter

National University Corporation Toyama: University of Toyama General Affairs Department, General Affairs and Public Relations Division (Public Relations)

Phone: 076-445-6028 FAX: 076-445-6063

E-mail: kouhou@u-toyamda.ac.jp

Chiyoda Corporation IR/PR/CSR Department Tsukamoto/Ikejiri

Phone: 045-225-7734 Fax: 045-225-7748

URL:https://www.chiyodacorp.com/jp/contact/index.php

Nittetsu engineering Corporation Sustainability and Public Affairs Department Public Relations Kano

Phone: 080-3208-0637

URL:https://www.eng.nipponsteel.com/contact/index.html

日本製鉄株式会社 総務部広報センター

電話:03-6867-2977

ハイケム株式会社 広報室 黒岩

電話:03-5251-8580

E-mail : kuroiwa@highchem.co.jp

三菱商事株式会社 広報部 報道チーム

電話: 03-3210-2171

Inquiries from the press regarding this release

HighChem Co., Ltd. Administration Division Eriko Kuroiwa

TEL: 03-5542-0580 E-mail:kuroiwa@highchem.co.jp