HighChem Company Limited (Headquarters: Chuo Chuo-ku, Tokyo President and CEO: Ushio Taka hereinafter referred to as HighChem), has established a business strategy partnership with Anhui Fuyuan Group Co., Ltd., a leading Chinese food additive manufacturer based in Bengbu, Anhui Province. On August 14, Anhui Fuyuan Futral Polylactic Acid Co., Ltd., a subsidiary of BBCA Group, successfully commenced mass production of Polylactic Acid (PLA). In response, HighChem is preparing its distribution framework in Japan to start selling PLA, along with initiating marketing activities for other biodegradable materials such as Polybutylene Adipate Terephthalate (PBAT).

The newly operational PLA manufacturing facility of BBCA Group boasts a current production capacity of 50,000 tons per year, which is planned to double to 100,000 tons per year by 2021. The long-term goal set by BBCA Group is to expand this capacity to 1 million tons per year within the next five years, significantly enhancing the supply of sustainable materials in the market.

1. What is PLA (polylactic acid)?

Feature 1: biodegradable resin

Biodegradable resins are types of plastic that decompose into water and carbon dioxide through the natural action of microorganisms present in the environment, seamlessly reintegrating into the earth's ecosystem. Polylactic Acid (PLA), a prominent example, degrades more slowly compared to other bioplastics, which allows it to be used in applications similar to conventional plastics. This characteristic enables PLA to provide an effective balance between usability in daily products and environmental responsibility, offering a sustainable alternative to traditional plastic materials.

Feature 2: Biomass resin

It is a resin manufactured from biomass resources such as corn, and has the characteristic that even if it is incinerated, it will not increase CO2 concentration, which contributes to global warming, due to the carbon neutrality of biomass.

Feature 3: Thermoplastic resin

It can be molded using various methods similar to general-purpose plastics, such as Extrusion molding and Injection Molding.

PLA is an eco-friendly resin that has features 1 to 3 above. It is attracting a lot of interest.

Additionally, products made from PLA have excellent biocompatibility, gloss, transparency, texture, and heat resistance. Furthermore, it also has antibacterial properties, so it can be expected to have a wide range of uses.

2. PLA market

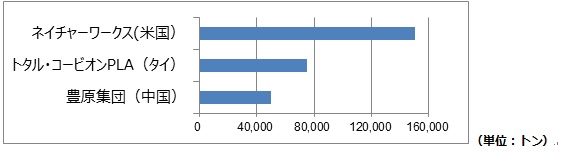

The global market for Polylactic Acid (PLA) was estimated at approximately 200,000 tons in 2019, with adoption particularly accelerating in Europe where demand is overtaking supply. In Japan, the market is estimated at around 5,000 tons, and supply constraints are also becoming evident. The recent completion of BBCA Group's plant, producing 50,000 tons per year, positions them as the third largest PLA supplier globally. With plans to expand production capacity significantly by 2022, BBCA Group is set to become the world's largest PLA supplier, aiming to meet the growing global demand and alleviate market shortages.

Global PLA Supplier Capacity

Global PLA Supplier CapacityHighChem 's initiatives

HighChem has recently started handling three types of products: Extrusion molding applications, Injection Molding applications, and fiber/ nonwoven fabric applications. Extrusion molding applications include films and sheets, and Injection Molding applications include food packaging containers for lunch boxes, vegetables and fruits, precision parts, and raw materials for compound. In addition, in textile and non-woven fabric applications, we will develop non-woven fabrics for apparel products, masks, tea bags, etc. Regarding textile applications, we will focus on the antibacterial and weakly acidic properties of polylactic acid and develop it into baby clothes and innerwear. Additionally, by collaborating with domestic apparel manufacturers, we aim to expand sales of PLA blended fibers and other products.

An example of a product using PLA

100% PLA polo shirt

50% PLA, 50% cashmere

PLA food packaging containers

4. HighChem's future initiatives and future prospects

In addition to doubling the distribution volume of PLA in the Japanese market by 2023, HighChem is developing PBAT (polybutylene adipate terephthalate), which has properties similar to general-purpose polyethylene, but is biodegradable in marine environment. We will also strengthen our handling of a wide range Biodegradable Materials, including materials that we have.

In addition, the problem of pollution of rivers and other areas in China is becoming a serious problem, and HighChem believes that Biodegradable Materials can be the key to solving the ocean plastic and microplastic problems. Currently, there is growing interest in these issues in China, and suppliers of Biodegradable Materials are emerging. As a Bridge between Japan and China, HighChem would like to build close relationships with these suppliers, serve as a bridge with Japanese materials manufacturers with high technological capabilities, and contribute to the worldwide spread of Biodegradable Materials.

Inquiries from the press regarding this release

HighChem Co., Ltd. Administration Division Eriko Kuroiwa

TEL: 03-5542-0580 E-mail:kuroiwa@highchem.co.jp