A Conversation with World-renowned Textile Designer, Kanako Kajihara

Last year, HighChem announced the next-generation PLA fiber, “HIGHLACT®,” accelerating the market development of PLA fibers both domestically and internationally. As apparel companies have begun to develop sustainable clothing due to issues such as clothing disposal, how does PLA fiber appear in the eyes of textile experts in the midst of this? And what kind of sustainable fibers are there that are indeed competitors to PLA fibers? Answering our questions was world-renowned textile designer Kanako Kajihara, who has a route to sell fabrics to overseas luxury brands. Kajihara, who has a deep insight into fashion and textiles from a global perspective, introduces the sustainable fibers she is focusing on.

CEO Creative Director Kanako Kajihara

Born in Sapporo, Hokkaido. After graduating from the Dyeing Department of Tama Art University’s Design Department, she joined Issey Miyake Textile Planning Co., Ltd. After resigning, she moved to the UK and completed a master’s course at the RCA Fashion & Textile course of the Royal College of Art. During her studies, she worked as a director, connecting the products of a weaving factory in Guatemala to the UK market, and found her calling in realizing that “design is a profession that connects people and society and becomes a bridge to the future.” She also won the Grand Prix at the design competition TEXPRINT2005, a gateway for newcomers in Europe, and paved the way for her to work as a freelance textile designer overseas. After graduation, foreseeing that the Japanese textile market would become tough, she returned to Japan with the desire to contribute to the reconstruction of Japan’s production areas. In 2006, she established KAJIHARA DESIGN STUDIO Inc. and has been involved in the development of global sales channels, trend marketing, and new business branding for local revitalization, with the aim of contributing to the future creation of Japanese textile production areas.

——What kind of work does a textile designer do?

Kajihara: I have mainly built a route to supply materials to European high maisons, so I propose fabrics developed at Japanese affiliated factories, or research and propose Japanese fabrics according to the requests from high maisons. I am also focusing on comprehensive branding of so-called DtoC products, as there has been an increasing demand to launch product brands from Japanese textile factories since 2015.

——Looking at your exposure in the media, it seems that you are also active as an expert in sustainable fibers?

Kajihara: In Europe, the concept of material exhibitions changed to focus on sustainability around 2016, influenced by the government. There has been an increase in opinions from European high maisons and American brands that they want us to increase the proposal of sustainable materials, and we have started to strengthen material development. On the other hand, in Japan at that time, the majority of opinions were negative, such as “If you incorporate threads and processing that are conscious of sustainability, the price will be high and it’s not real for sales. It’s not the needs of users. It’s a concept collapse.” However, in recent years, Japan has also been experiencing climate change such as typhoons and rising temperatures, and through the Corona issue, information on global warming and environmental destruction is spreading in society, education is starting in schools, and awareness of sustainability is gradually changing. I think this trend is definitely coming to China as well. In fact, the projects I am involved in have increased all at once in 2021 in relation to sustainability.

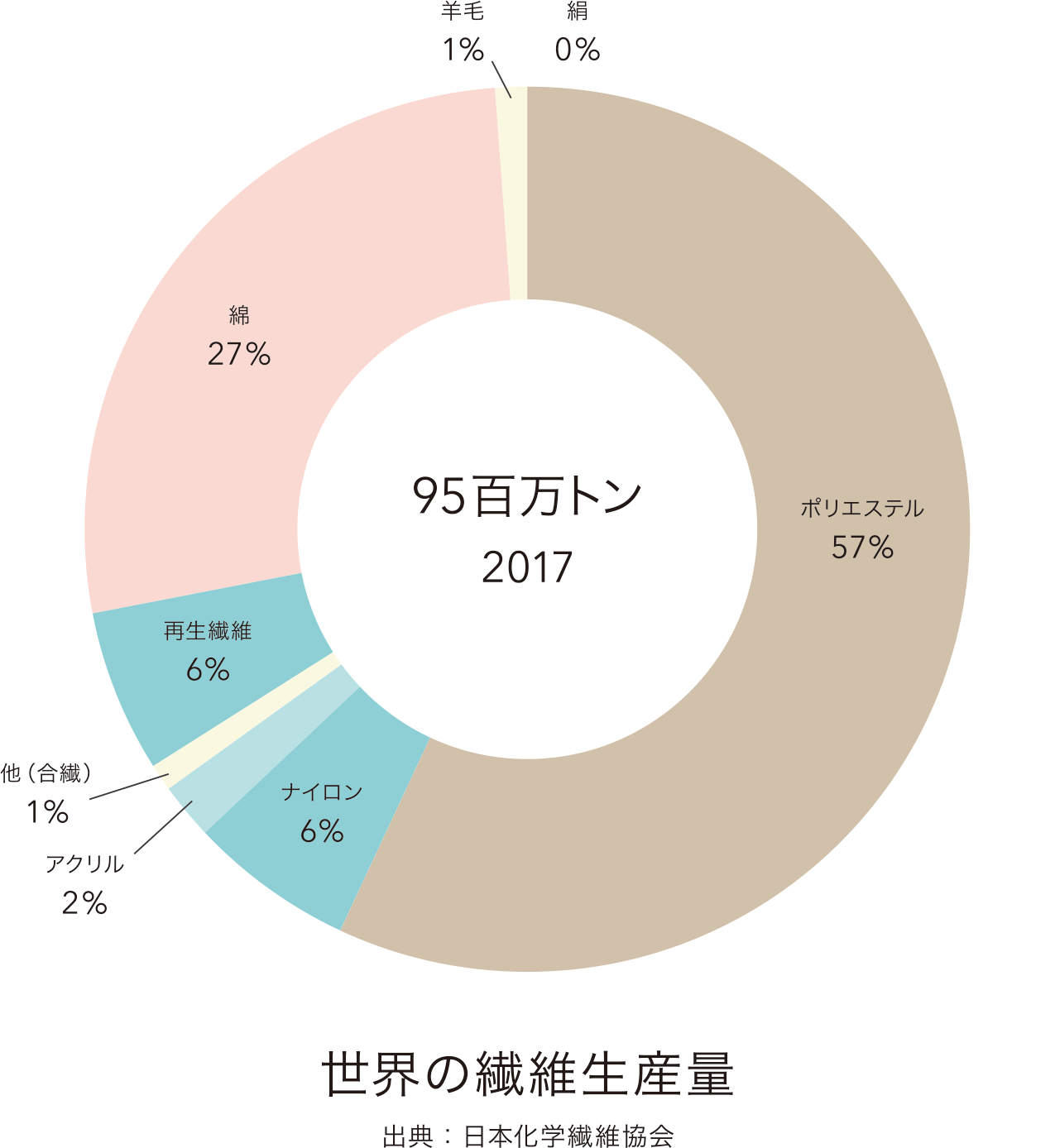

——Currently, polyester and cotton account for the majority of fiber production, but what kind of state do you think the current composition of these fibers should be in in order to be a sustainable goal for the textile industry?

Kajihara: I think the textile industry aims to consolidate into two places. One is “to change to materials that return to the soil” and the other is “to realize a circular economy by continuing to recycle and reduce waste.”

——Could you tell us about the sustainable fibers that you are focusing on in order to achieve these goals?

The main raw materials are natural materials, which are divided into “plant fibers” and “animal fibers”. The main raw materials are “plant fibers” such as cotton and linen. Also, “animal fibers” are those that use silk, cashmere (goat), and wool as the main raw materials.

Linen (Hemp)

Kajihara: Among plant-based natural materials, linen, hemp, jute, and paper yarn are attracting attention. In order to achieve carbon neutrality, it is necessary to not reduce greenery. In that respect, the plants of these raw materials grow quickly even if they are cut down, so the burden on the environment is small. It’s also good that they grow without using a lot of water. I think cotton is used a lot among the natural materials, but in the future global market, I think the trend of actively using hemp-based materials will increase.

Sustainable Silk

Kajihara: With animal fibers, the issue of animal protection comes to the fore. There is also sustainable silk that eats mulberry leaves without pesticides, but it is a fact that there are people who see it as not SDGs because even insects are life. Therefore, even in silk, a thread called Peace Silk, which is taken out before killing the silkworm and makes the remaining cocoon into a thread, is attracting attention.

The main raw materials are petroleum and artificially made polymers, which are divided into “synthetic fibers” and “regenerated fibers”. Polyester and nylon are “synthetic fibers” that use petroleum-based raw materials, while rayon and Tencel are “regenerated fibers” refined from natural wood and other materials.

Recycled Polyester

Kajihara: The European market is focusing on chemical recycling. In France, a clothing disposal ban has been in effect since January 2022. As a result, clothing collection boxes have been set up in cities. The demand for repair, reuse, and recycling of clothes from clothes will continue to grow in the future. However, the reality is that there are still very few facilities in the world that can do chemical recycling. There is only one plant each in Japan and China. I think we cannot talk about the domestic recycling system in Japan unless there are a few more plants. Also, a large amount of energy is required for recycling, so there are still unresolved issues in contributing to carbon neutrality.

Regenerated Fiber Cupra & Lyocell

Kajihara: What I am focusing on, as a material that returns to the soil, is regenerated fiber refined from natural wood and other materials. In the industry, Asahi Kasei has gained a global share with the trademark name “Bemberg”, and “Lyocell fiber” represented by “Tencel” manufactured by Lenzing in Austria. Especially Lenzing has a reputation as a sustainable company, so there is a sense of security when adopting the fabric. Also, they use wood procured from forests that have been properly managed up to logging, and they have also obtained FSC (forest) certification.

Next-generation Cellulose Fiber’s Big Hope Rayon Material “KUURA (KUURA)”

Kajihara: Rayon is the first chemical fiber developed as a substitute for silk. However, in reality, organic solvents are used in the production process, and it is said that making rayon is dangerous enough to explode once a year. This Kuura is a rayon that Itochu develops jointly with Metsa Group, the world’s largest wood pulp in Finland. Since it is manufactured with a revolutionary method that is almost unchanged in cost and has less danger, it is said to be the big hope of next-generation cellulose fiber. It has obtained FSC certification and many other certifications and is very promising, but it seems that there is no prospect of mass production yet. I look forward to future developments.

Biodegradable Fiber PHA (PHBH, PHBV, etc.)

Kajihara: I am very interested in PHA, which has marine degradability, among biopolymers. It might be good to develop fishing nets that do not pollute the ocean instead of nylon. To give an example from a more familiar perspective, when synthetic fibers are washed, the amount of microplastics that ends up in the ocean is not negligible, and there are concerns about the impact it could have on the marine environment. It is particularly worrisome that it flows out from fleece by washing, but if fleece that fits within the appropriate price range made of PHA is developed, it may become popular among brands and users with high sustainability consciousness. However, it is difficult to mass-produce PHA, and there are problems with the physical properties when it is fiberized due to the nature of the resin, so I hope for further improvements.

PLA Fiber

Kajihara: PLA fiber is not yet the central material in apparel, but I think it will attract more and more attention in the future. It can be said to be a “neo-polyester” that solves the problem of polyester being derived from petroleum and not decomposing in the soil. It’s good that a thread that has improved the heat-sensitive characteristics that have been a problem so far has been made, and it is also good in terms of expectations for mass production.

——What do you think are the current challenges for PLA fibers?

Kajihara: The problem might be that it is close to polyester, for better or worse. It has the atmosphere of old synthetic fibers. The impression is that the development of processing has not progressed sufficiently because the previous PLA fibers were weak when heated. The texture is not appealing when touched, and there is no natural atmosphere that is currently required for synthetic fibers. The impression is that there are still few variations in design in yarn and material development. This is the case whether it is long fiber or short fiber. If various variations such as glossiness, matte feeling, tension, and softness are developed, it will be easy to use. Personally, I expect that PLA can express a texture close to natural fibers because it is a fiber that returns to the soil.

Also, clothes that need polyester are more in the sports industry, I think. In sportswear, various functionalities such as quick-drying, moisture-permeable waterproofing, water repellency, UV cut, anti-pilling, and anti-transparency are required. I think interest will increase if PLA research is done up to a point bringing it close to the quality numbers of polyester.

It is also a challenge to convey the concept of PLA to consumers and to permeate it into society. I think it will still be difficult to consider the merits of price. So, I think we need the power of words and design to convey how to add value and make it valuable. For that, development of price tags and pops will be necessary.

——What do you expect from HighChem, which supplies PLA fibers?

Kajihara: The ability to stably supply heat-resistant polylactic acid resin is a major strength of your company. I hope you will expand the variation of threads and expand the possibilities of material design such as woven fabrics, knitted fabrics, and tape materials together with Japanese factories. There are still many textile manufacturers with high technology in the local area. I look forward to opening up a new future for PLA materials by teaming up with them. Not only clothes, but I think it has the potential to change materials to plant-derived materials for plastic products related to the next generation of life.