ポリエーテルアミンはプロピレンオキサイド (PO)、エチレンオキサイド (EO)、又はPO/EOの混合からなるポリエーテル部を持ち、アミン官能基数や分子量の異なる各種ラインアップが有り、エポキシ硬化剤、ポリウレアコーティング原料、樹脂改質材、金属加工油剤、燃料添加剤等幅広い用途に採用されています。

基本情報

英語名

Polyetheramines

製品の特長

主な用途

- エポキシ樹脂用途

風力発電のブレード

道路の補修材(ひび割れした箇所に注入)

各種接着剤

自動車部品など

塗料

装飾材 - ポリウレアコーティング

道路、駐車場の路面、建物の床材(スプレーで吹き付けてコーティングします) - 樹脂改質剤(ポリアミド樹脂など)

特長

無色透明で透明性、美観を必要とする用途のみならず、このポリエーテル構造を持つ事から

- エポキシ硬化物が柔軟性を持ち、優れた伸張性、耐衝撃力、低温特性を発揮します。

- 粘度が比較的低い為ハンドリングが容易で溶媒の使用量を低減させる事が出来ます。

- 立体障害構造を持ち反応を遅延させ、適度なポットライフを提供します。

- 他の硬化剤と比べると比較的低い毒性プロファイルを示します。

製造国

中国

主な製品

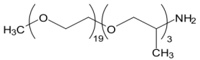

モノアミン

平均分子量 |

基本骨格 |

用途 |

構造式 |

|---|---|---|---|

1000 |

PO/EO |

エポキシ樹脂乳化剤、防錆剤 |

|

1000 |

PO |

潤滑油・燃料添加剤 |

|

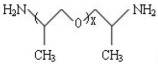

ジアミン

平均分子量 |

基本骨格 |

用途 |

構造式 |

|---|---|---|---|

230 |

PO |

エポキシ樹脂硬化剤 |

X ≒ 2.5 |

400 |

PO |

エポキシ樹脂硬化剤 |

X ≒ 6 |

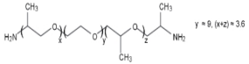

2000 |

PO |

ポリウレアコーティング基材 |

X ≒ 33 |

600 |

PO/EO |

電子材料 |

|

1000 |

PTMEG/PO |

樹脂改質材 |

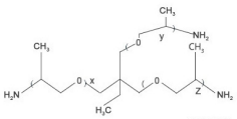

トリアミン

平均分子量 |

基本骨格 |

用途 |

構造式 |

|---|---|---|---|

440 |

PO |

エポキシ樹脂硬化剤 |

x + y + z = 5 ~ 6 |

3000 |

PO |

エポキシ樹脂硬化剤 |

x + y + z = 50 |