ハイケム株式会社(本社:東京都港区 代表取締役社長:高潮(たか うしお)、以下ハイケム)と株式会社リコー(本社:東京都大田区 社長執行役員:山下良則(やました よしのり)、以下リコー)は、脱炭素社会の実現やマイクロプラスチックによる環境汚染低減といった社会課題解決への貢献を目指し、生分解性のバイオマスプラスチックである高分子量PLA※1を、超臨界二酸化炭素を用いて量産化するための開発を共同で行うことに合意し、基本合意書を2021年11月25日に締結しましたのでお知らせします。

※1 高分子量PLA:重量平均分子量30万以上のポリ乳酸

(左)株式会社リコー

リコーフューチャーズビジネスユニット

プレジデント 入佐孝宏(いりさ たかひろ)

(右)ハイケム株式会社

代表取締役社長 高 潮(たか うしお)

リコーの「高分子量PLA」製造技術とは?

超臨界二酸化炭素で強靭なPLAを製造

PLAはトウモロコシなどに含まれるデンプンを原料とした植物由来のプラスチック素材です。焼却しても大気中の二酸化炭素を増加させない(カーボンニュートラル)ため、化石由来のプラスチックよりも環境負荷が低くなります。また、一定の環境下で水と二酸化炭素に分解する(生分解性)ため、マイクロプラスチック化しても自然環境下で分解し、環境汚染の低減が期待できます。一方で、化石由来のプラスチックと比べると分子量が低く、化学構造が単純なため、強度や耐熱性が低いことが問題になっています。リコーは、これまで培ってきた超臨界二酸化炭素を用いた可塑化重合法で、高分子量PLAを製造する技術を保有しています。

『ハイケム×リコー』だからできること

高分子量PLA共同開発の目的

今般の共同開発の目的は、リコーが保有する重合技術を検証し、高分子量PLAを試作することで、より付加価値の高い製品を世の中に提供していくことです。将来的には、高分子量PLAの量産化実現を目指していきます。この共同開発を実現させることで、リコーの開発した発泡PLAシート「PLAiR(プレアー)」の品質向上や、ハイケムが開発したPLA繊維「HIGHLACT™(ハイラクト™)」の品質向上、工業用品などに用いられる耐熱性の高いエンジニアリングプラスチックなどへの用途開発を図ってまいります。さらには、この高分子量化の技術を他の生分解性樹脂へも展開してまいりたいと考えております。なお、本プロジェクトは、ハイケムの東京研究所(千葉県柏市)と、リコーの沼津事業所(静岡県沼津市)およびリコーテクノロジーセンター(神奈川県海老名市)にて実施する予定です。

リコーがこれまで培ってきた技術力とハイケムの日中の架け橋としての実績を掛け合わせることにより、社会課題の解決につながる新しいPLA製品を一日も早く世界のより多くの人々に提供できる未来を実現してまいります。

生分解性プラスチックにおけるリコーの強み

1. 「環境経営」への取り組み

リコーグループは、1998年から環境保全と利益創出の同時実現を図る「環境経営」に取り組んでいます。脱炭素型社会の実現に向け、化石由来プラスチックの代替素材普及は喫緊の課題です。リコーはPLAを原料としたバイオマスプラスチックを複合機の部材として採用したり、独自技術によりPLAを発泡させた「PLAiR」を開発・販売しています。

植物と空気からできた新素材「PLAiR」

植物と空気からできた新素材「PLAiR」

2.PLAをはじめとする生分解性プラスチックの成型加工技術

PLAは成形加工が難しいため、改質のために化石由来の樹脂を混合する場合があります。すると、カーボンニュートラルや生分解性といった利点が損なわれてしまうことに加え、加工費などでコストが高くなってしまうため、市場への投入が進んでいません。

リコーは、これまで培ってきた超臨界二酸化炭素の技術をPLAの重合反応に応用することで、PLAの分子量を高めたペレットの生成に成功しました。添加剤や他の化石由来樹脂を混ぜる必要がなくなるため、成型加工品のコストアップを抑制できることに加え、環境負荷の低いPLAの利点を損なうことなく素材の高強度化が可能です。

生分解性プラスチックにおけるハイケムの強み

1. 生分解性プラスチックのトータルソリューションを提供

ハイケムは中国最大のPLAメーカー豊原集団と事業戦略パートナーシップ契約を締結するなど、生分解性プラスチックのマーケット開拓にいち早く取り組んでまいりました。また、PLAだけでなくPBAT(ポリブチレンアジペート/テレフタレート)やPHBVなど合計7種類の生分解性プラスチックを輸入する体制を整えており、生分解性プラスチックのトータルソリューションカンパニーとなるべく活動を強化しています。

2. PLA繊維のマーケットを開拓

ハイケムでは、CHEMTEX(CHEMICAL=ハイケムがこれまで培ってきた化学分野でのチカラ × TEXTILE=日本の卓越した伝統的な織物技術や染色技術)により実現した、次世代PLA素材HIGHLACT™(ハイラクト™)を2021年12月1日に発表しました。ハイラクト™では、樹脂原料から生地までの一貫生産管理によるPLA繊維の品質向上を実現しており、アパレルメーカーなどへ対しマーケット開拓を行っています。また、日中の架け橋として培ってきた市場開拓力を武器に、中国をはじめとする世界の生分解性マーケットの市場を開拓してまいりたいと考えています。

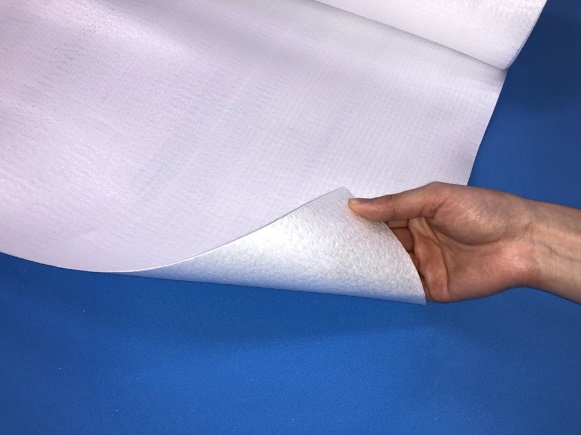

ハイラクト™生地

ハイラクト™生地

株式会社リコー 概要

会社名:株式会社リコー

所在地:東京都大田区中馬込1-3-6

社長執行役員:山下良則 (やました よしのり)

事業内容:オフィスサービス・オフィスプリンティングをはじめ、商用印刷・産業印刷、サーマル・産業プロダクツ・デジタルカメラ等の製造・販売

ハイケム株式会社 概要

会社名:ハイケム株式会社

所在地:東京都港区虎ノ門1丁目3番1号 東京虎ノ門グローバルスクエア11階

代表取締役:高潮(たか うしお)

事業内容:化学品の輸出入販売・受委託製造/技術ライセンス関連業務/触媒製造販売/生分解性材料輸入販売等

【このリリースに関する報道機関からのお問合せ】

ハイケム株式会社 広報室 担当:黒岩(090-6539-4213)

TEL:03-5251-8580 E-mail:koho@highchem.co.jp

株式会社リコー 広報室

TEL:050-3814-2806 E-mail:koho@ricoh.co.jp

URL:https://jp.ricoh.com/