“捨ててもいい服”が未来のファッション業界を変える

ハイケム株式会社(本社:東京都港区 代表取締役社長:高潮(たか うしお)、以下ハイケム)は、アパレル各社も強化している「脱プラスチック」、「サステナブルファッション」の取り組みに着目し、取り入れることでCO2削減に繋がる新素材「HIGHLACT®(ハイラクト®)」を開発。12月7日〜9日に東京ビッグサイトで開催される「エコプロ2022」にブースを出展し、HIGHLACT®で出来た服の展示およびドレスを着用したファッションショー、また当社および繊維関連企業が「未来の服」について語るトークセッションを開催いたします。

さらに、今般開発に成功したHIGHLACT®からできたデニム、フリース、ニット、サテン生地などを展示します。実際にHIGHLACT®素材をお手に取り触って頂くことができる貴重な機会です。

【会場】東京ビッグサイト 東6ホール 小間番号 6-031(一般出展)

HIGHLACT®を導入することで、CO2排出を年間約200万トン(※1)削減できる可能性も!

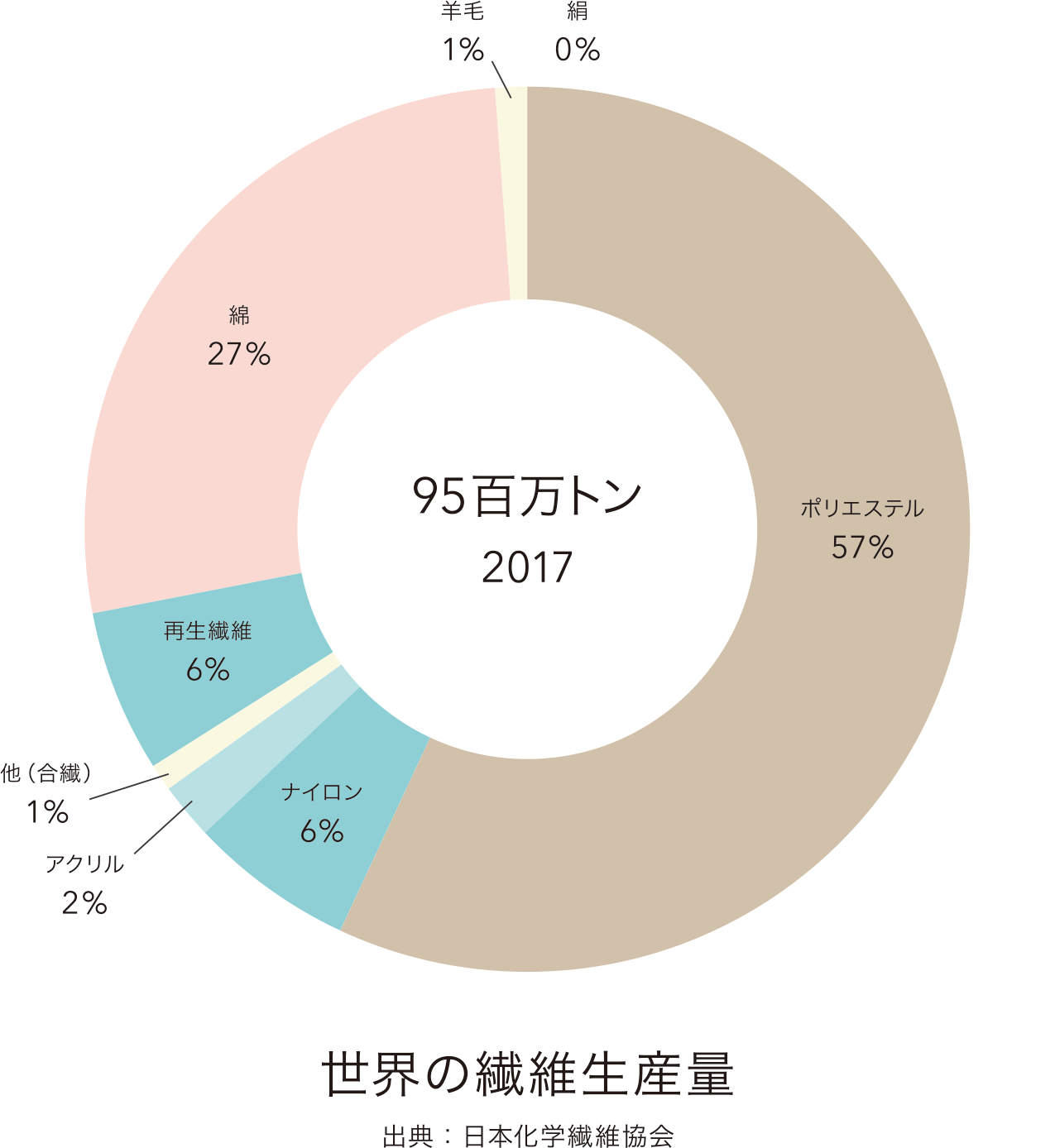

CO2の削減は、国際問題として多くの企業を筆頭に世界中で様々な取り組みが行われています。世界の繊維産業から排出されるCO2は全産業の8%を占め、ファッション業界においても課題となっています。

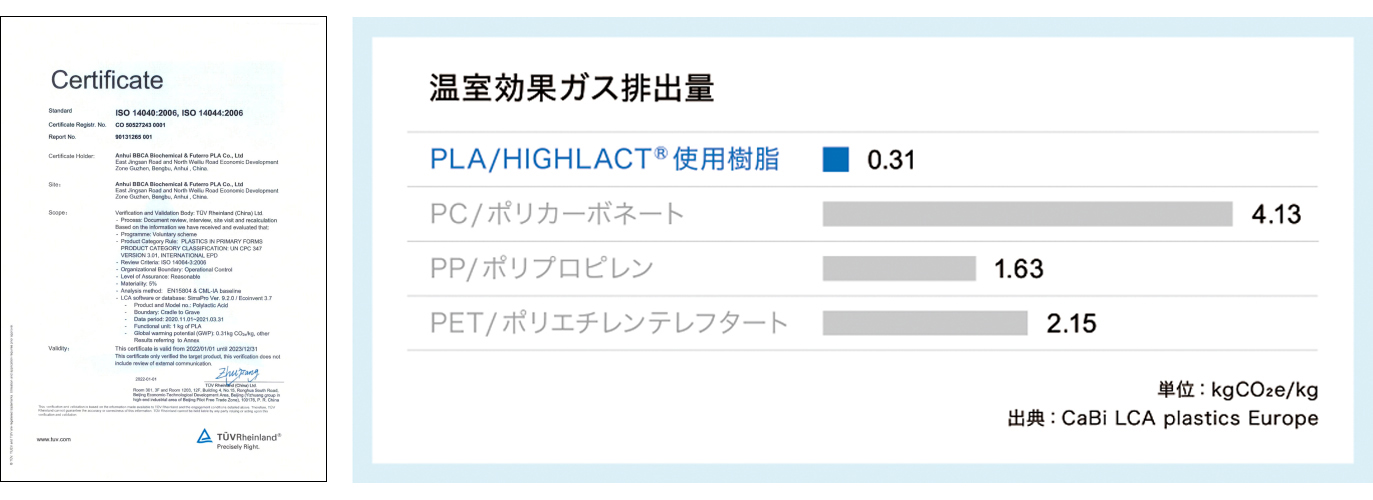

トウモロコシ由来のPLA(ポリ乳酸)から生まれた素材であるHIGHLACT®は、原料の製造過程で排出されるCO2はポリエステル比で約1/7(※1 参照)となり、素材を切り替えることでCO2削減効果が見込めます。仮に日本中のポリエステル製の洋服をHIGHLACT®に置き換えたと仮定すると、原料製造時のCO2を年間約200万トン削減することができる想定となります。これは日本人100万人が年間に排出するCO2量です。さらに、PLAは原料の生育過程においてCO2を吸収するため焼却しても大気中のCO2は差し引きゼロになるカーボンニュートラルな性質を有しているので、更なるCO2削減効果を期待できます。

HIGHLACT®で作られた服でのファッションショー開催!最新トレンド服やドレスなど全4シーン

ハイケム取締役 高裕一が登壇!「未来のファッション」について語るプレゼン開催

ハイケムと繊維関連企業2社によるトークショー開催。 HIGHLACT®繊維開発企業対談が実現

ブースは、生地・素材を風景に見立てた「日本庭園調」に装飾

パンチカーペット(原料製造時のCO2約53%削減 ※2)やグラフィックパネル(原料製造時のCO2約72.5%削減 ※3)にもPLA素材を使用

国内の染色技術で7色に染めたPLA100%の生地を暖簾風にして展示。実際に生地を触れる体験

今般開発に成功した、デニム、フリース、ニット、サテン生地を屏風として展示

「beautiful people」などパリコレブランドに採用!当日は「beautiful people」の服も展示

HIGHLACT®製品情報

トウモロコシ由来のPLA(ポリ乳酸)から生まれた新素材

PLA(ポリ乳酸)の3つの特徴

PLA(ポリ乳酸)は原料にトウモロコシなどのバイオマスを使用しているので植物の生育過程でCO2を吸収しており、焼却しても大気中のCO2は差し引きゼロになるカーボンニュートラルな素材です。

また、一定の条件下で水と二酸化炭素に分解される生分解性を有しており、製品の使用後は自然に還る理想的なサイクルを実現できます。

更に、乳酸を原料とするため天然の抗菌性を有しており、近年繊維素材として注目を集めています。

「化学のチカラ × 日本の伝統文化」で開発されたHIGHLACT®

HIGHLACT®の原料であるPLA(ポリ乳酸)は、既存のプラスチックと比べると強度が低く、耐熱性も低いことから、これまで繊維には不向きの原料とされてきました。私たちハイケムはこれまで培ってきた化学分野での技術と、日本の伝統的な織物技術や染色技術の融合により、HIGHLACT®の開発を実現しました。

展示中のイベントのご案内

● HIGHLACT®オリジナルファッションショー

スケジュール:1日5回開催予定、各10:30~、12:00~、13:00~、14:00~、15:00~

● ハイケム 企業プレゼンテーション

登壇者:ハイケム サステナベーション本部 本部長 高裕一取締役

テーマ:ファッションに「捨ててもいい」選択肢を─次世代サステナブル素材 HIGHLACT®

スケジュール:1日2回開催予定、12月7日・9日(13:10~、15:10~)12月8日(10:40~、15:10~)

● HIGHLACT®開発企業によるトークセッション

登壇者:小野莫大小工業有限会社 取締役 高橋幸太郎氏、タキヒヨー株式会社 マネージャー 中嶋正樹氏、ハイケム サステナベーション本部 本部長 高裕一

テーマ: HIGHLACT®開発秘話(仮)

スケジュール:12月8日 13:10~、12月9日 10:40~

※スケジュールは事前の予告なく変更になる場合があります。予めご了承くださいませ。

社名:小野莫大小工業有限会社

本社所在地:東京都江東区亀戸1-42-20 住友不動産亀戸ビル11

代表取締役:小野元延

事業内容:各種繊維素材、繊維製品加工販売

URL:https://www.onomeriyasu.jp/

社名:タキヒヨー株式会社

本社所在地:愛知県名古屋市西区牛島町6番1号 名古屋ルーセントタワー23・24階

代表取締役:滝 一夫

事業内容:繊維製品卸売業

URL:https://www.takihyo.co.jp/

HIGHLACT®採用ブランドの展示

beautiful people 様

beautiful people 様

展示Tシャツ Playful Feels T/てあそびロンT

会場アクセス

会場:東京ビッグサイト 東6ホール

所在地:〒 135-0063 東京都江東区有明3丁目11-1 1階

アクセス:りんかい線「国際展示場駅」下車 徒歩約7分、ゆりかもめ「東京ビッグサイト駅」下車 徒歩約3分

会社情報

会社名:ハイケム株式会社

所在地:東京都港区虎ノ門1丁目3番1号 東京虎ノ門グローバルスクエア11階

代表取締役:高潮(たか うしお)

事業内容:化学品の輸出入販売・受委託製造/技術ライセンス関連業務/触媒製造販売/生分解性材料輸入販売等

取材申込フォーム

ご多忙とは存じますが、何卒ご来場くださいますようお願い申し上げます。

ご来場いただける場合は、参加フォームにてお申込みくださいますよう、お願いいたします。

取材申込フォーム

※ご来場いただけるお時間の目安をご記載くださいませ。

※申込〆切 12月6日(火)18:00

※1 ハイラクト®を採用することで可能になる年間CO2削減量=約200万トン

算出根拠:

1. 日本国内の繊維産業における原料調達に関るCO2排出量:2341万トン

国内ファッション産業におけるCO2排出量:9705万トン

出典:2020年3月 株式会社日本総合研究所資料より

2. 世界の繊維生産量に占めるポリエステルの割合:57%

出典:日本化学繊維協会

3. PLAとポリエステルの生産時のCO2排出量の違い

PLA(ポリ乳酸) =0.31kgCO2e/kg

PET(ポリエチレンテレフタート)=2.15kgCO2e/kg

上記、1、2、3より算出

2341×0.57 × 0.31/2.15=192.39 万トン(※1)

原料調達時のCO2排出量 × ポリエステルの占める割合×PLA/ポリエステルCO2排出量

※2 パンチカーペットの原料製造時のCO2削減量

従来品:ポリプロピレン(PP)100%との比較

製造時:大きさ1490×厚さ0.9=1341

1341−(502×1.24)622.48=718.52(kg-Co2/t)

718.52÷1341= 約53%削減

※3 グラフィックパネルボードの原料製造時のCO2削減量

従来品:ポリスチレン(PS)100%との比較

A:製造時:大きさ1890×厚さ1.2=2268

2268−(502×1.24)622.48=1645.52(kg-CO2/t)

1645.52÷2268=約72.5%削減

【このリリースに関する報道機関からのお問合せ】

ハイケム株式会社 広報室 担当:黒岩(090-6539-4213)・陳

TEL:03-5251-8580 E-mail:koho@highchem.co.jp