ネプコン ジャパン2025開催報告

『デバイスの未来をサポート 次世代の最先端部材ならハイケム』というテーマのもと、ハイケムが取り扱う最先端の部材を「次世代電子部品」「次世代型太陽電池材料」「半導体材料」の3つのカテゴリーで出展しました。

今回は、展示会で特に注目を集めた「次世代電子部品」について、出展担当者の閆(えん)よりご紹介させていただきます!

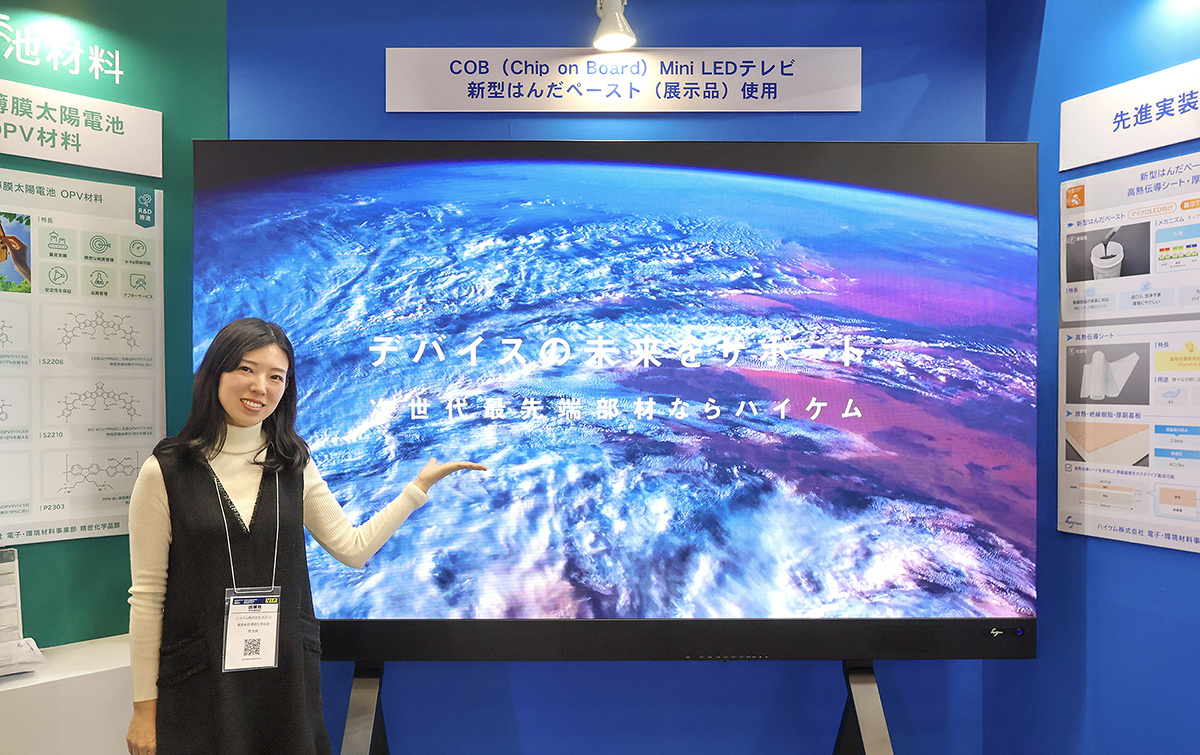

Mini/Micro LED対応の「新型はんだペースト」

「新型はんだペースト」を使用した108インチのMini LEDテレビを展示

「新型はんだペースト」を使用した108インチのMini LEDテレビを展示

展示会場でひときわ存在感を放っていたのが108インチの巨大Mini LEDテレビです。このテレビには、ハイケムが研究開発パートナーと共同開発した「新型はんだペースト」が採用されています。

「はんだは、電子機器製造に不可欠な接合材料として幅広く使用されていますが、近年、ウェアラブル端末などの普及により、電子機器の小型化が加速し、はんだをはじめとする接着材料には、より高い精密性が求められています。」と閆さんは語ります。

「新型はんだペースト」の特長について、閆さんに詳しく聞いてみました。

◆ 特長1 特殊樹脂によるコーティング

最大の特長は、独自開発した特殊樹脂がはんだの金属粒子をコーティングしている点です。この樹脂により、従来の樹脂を含まない製品と比較して、高い絶縁性、接着性、安定性が実現しています。

◆ 特長2 微細部品に対応

最新のMicro LEDのディスプレイにおいては、100μm以下の極小のLEDを平面上に配置する必要があります。そのため、従来のはんだでは対応が難しく、ショートしてしまうなどの問題がありますが、新型はんだペーストは、30μmという微細なスペースにも対応できる設計になっています。

◆ 特長3 ワンストップで環境に優しい接合が可能

従来のはんだ工程では、アンダーフィル(底部充填)や洗浄が必要でした。しかし、新型はんだペーストは特殊な樹脂を含んでいるため、これらの工程を省略でき、ワンストップかつ環境に優しい接合が可能となりました。

「新型はんだペースト」はMini/Micro LEDなどのディスプレイ用途はもちろん、4Gや5Gなどの高速通信機器やウェアラブル端末の接合材料にも用いることができるそうです。

パワーデバイス対応の放熱材料「高熱伝導シート」

高い熱伝導率を有する「高熱伝導シート」

高い熱伝導率を有する「高熱伝導シート」

「新型はんだペースト」と並んで注目を集めたのが、先進実装材料「高熱伝導シート」です。樹脂にセラミック粉体を配合してシート状にしており、15W/mK(ワット/メートル・ケルビン)以上の高い熱伝導率、接着力、絶縁性を実現しています。この革新的な製品について閆さんより説明させていただきます。

従来の放熱材料は主にセラミック製が主流でしたが、いくつかの課題がありました。例えば、銅箔との膨張率の違いによる歩留まり率の低下や、シートの厚みによる設計自由度の制限やコストの問題などです。

ハイケムが開発パートナーと共同で開発した高熱伝導シートは、特殊な樹脂を使用しており、シートの厚みを0.05mm~0.1mm程度まで薄くすることに成功しました。これにより、軽量化や低コストを実現できる画期的な製品となりました。

今回紹介する「高熱伝導シート」は、エアコンなどの家電はもちろん、EVや電車、太陽光発電などのパワーデバイスにも利用可能とのことです。また、IGBTなどの大電流に対応する「厚銅基板」と「高熱伝導シート」をセットにしたカスタマイズ製造も可能で、よりお客様のニーズに合わせた放熱材料のソリューションの提供が可能です。