Ceramic binder "Serander®"

"Serander®", a binder for ceramic molding, is an all-in-one product with added binders and plasticizers.

* HighChem acquired the new ceramic binder business (NCB business) from YUKEN INDUSTRY CO., LTD. in January 2020.

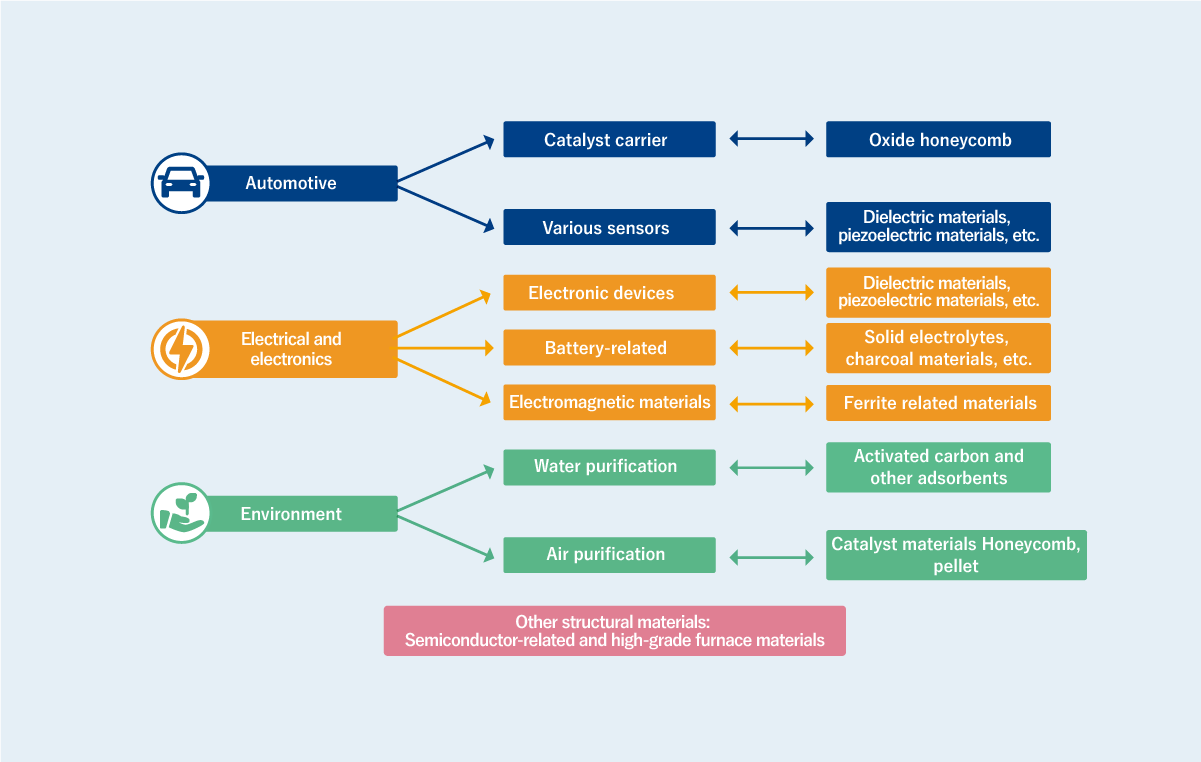

Various fields where Serander is used

Serander® is used in various fields and applications

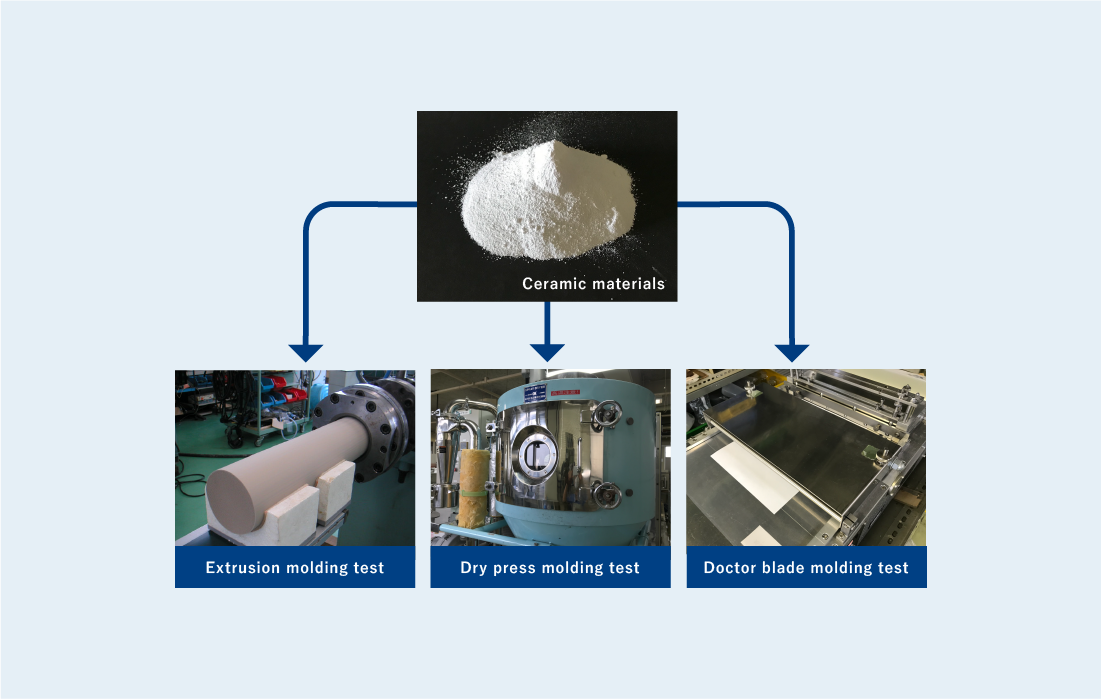

Made-to-order system according to customer's request

We can propose a custom-made binder system that meets your needs such as molding method, target shape, size, etc.

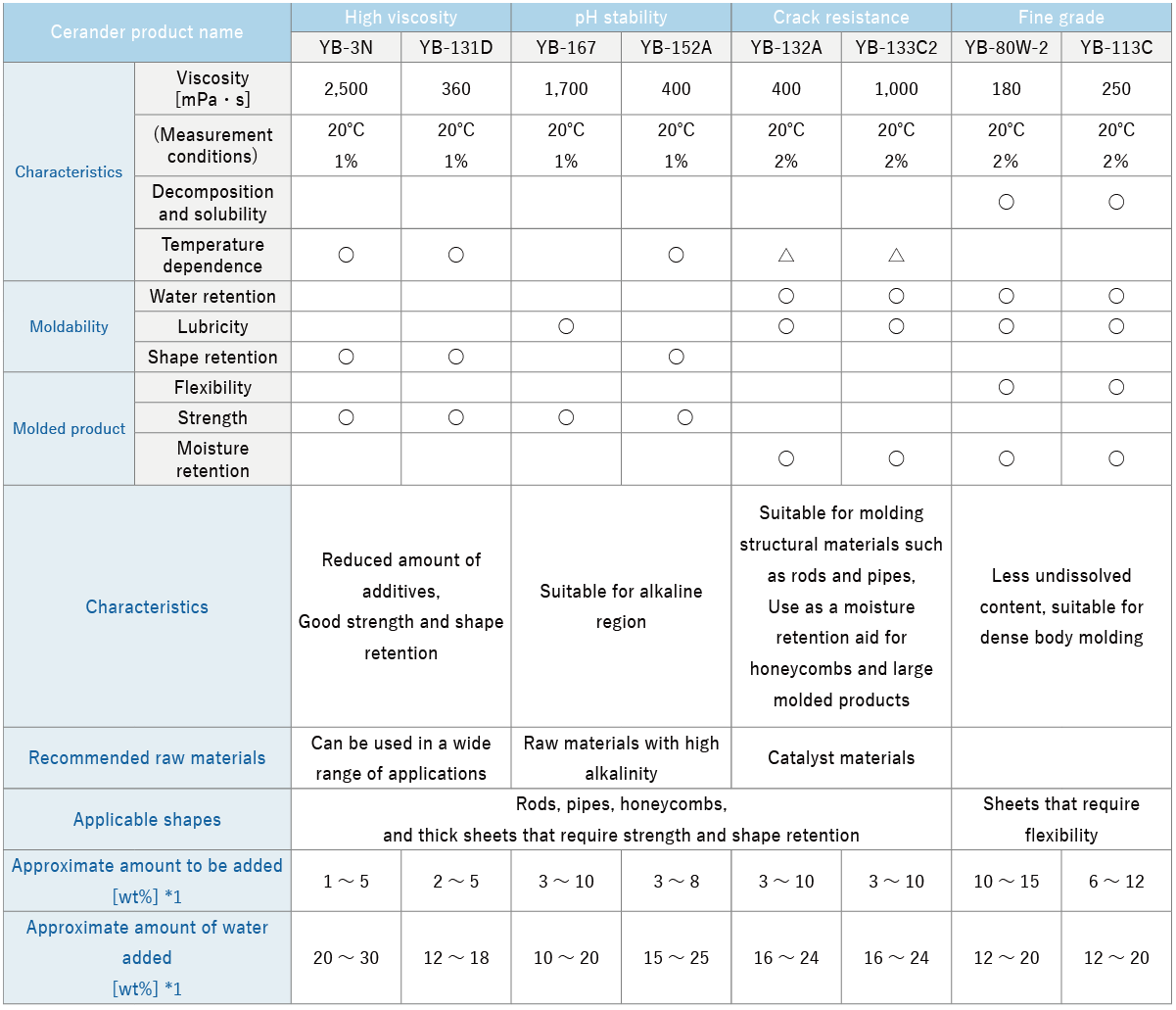

Extrusion molding binder

The extrusion molding binder is mainly composed of a methyl cellulose derivative. For shapes such as rods and pipes, we can propose a selection that emphasizes shape retention, and for sheets or similar shapes that require flexibility, we can propose a binder that emphasizes flexibility and rolling performance.

Product characteristics

* 1 The amount of Serander added and the amount of water added are the case when used for an inorganic raw material with a specific gravity of about 4 (average particle size of about 1 μ).

In addition to the products listed, we also offer a variety of solvent-based products. Please contact us for more information.

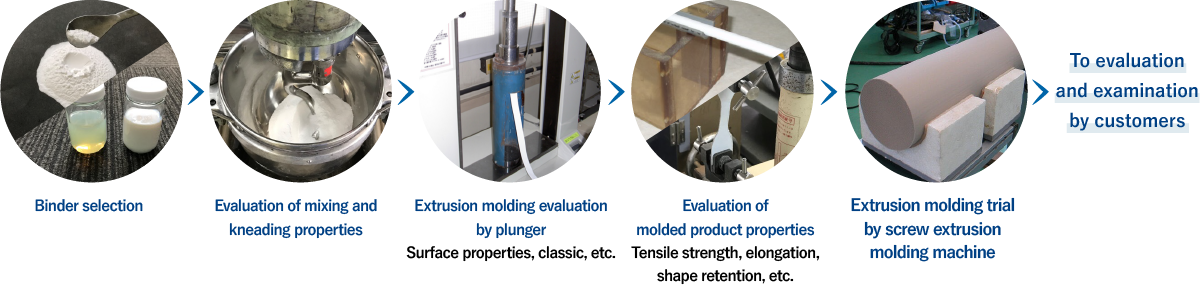

Extrusion test process

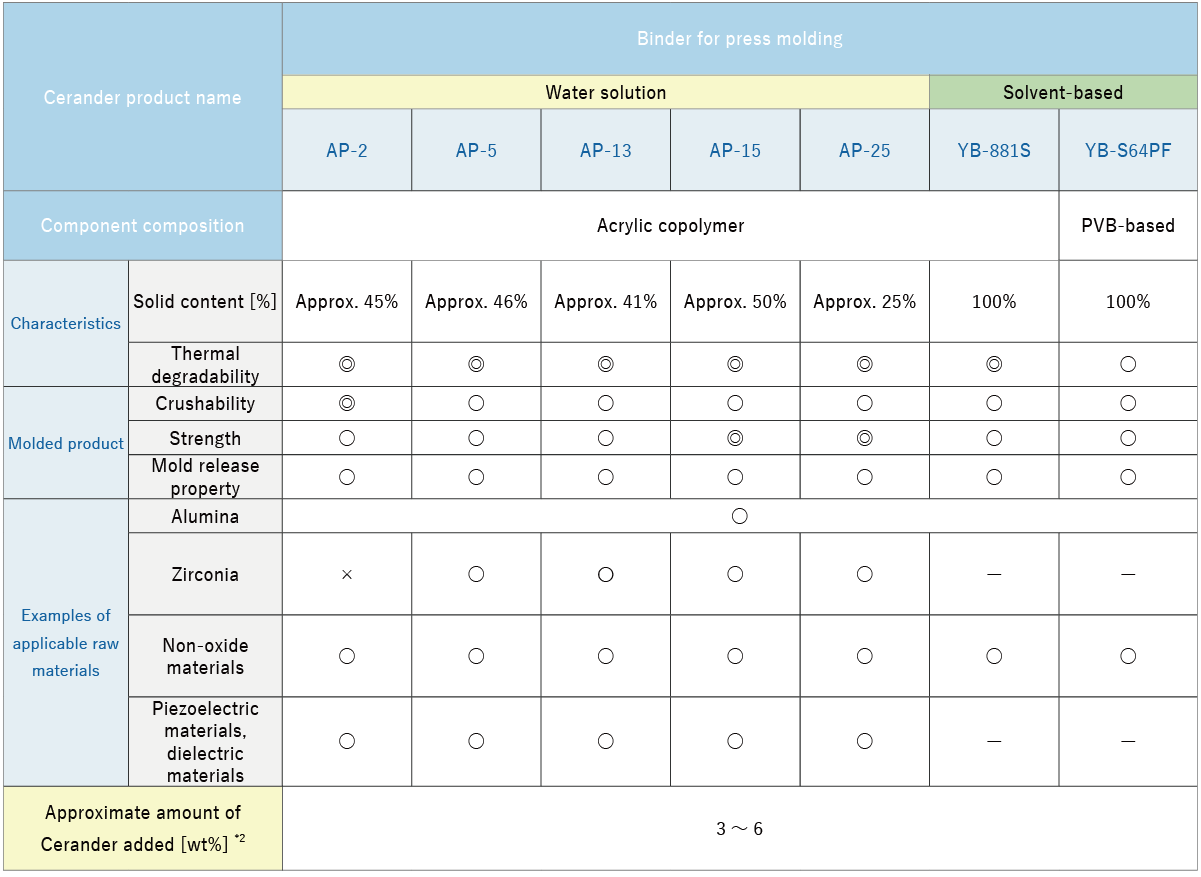

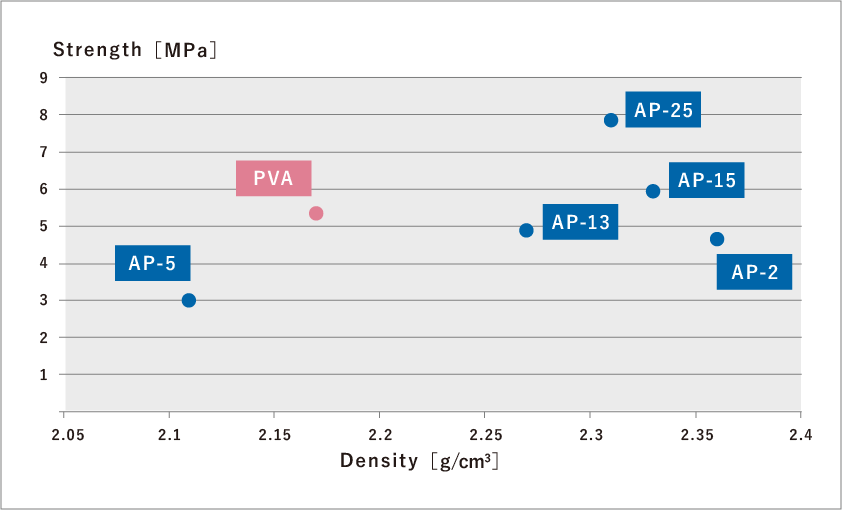

Binder for dry press molding

Since water-based press-molding binders are mainly composed of polyacrylic acid-based copolymers, we offer a lineup of binders that make it easier to obtain molded products with higher production strength and density than PVA. We also offer some solvent-based binders for water-repellent raw materials.

Product characteristics

*2 The amount of Serander added is the value in terms of solid content, which is the outer weight versus 100 parts by weight of the raw material powder.

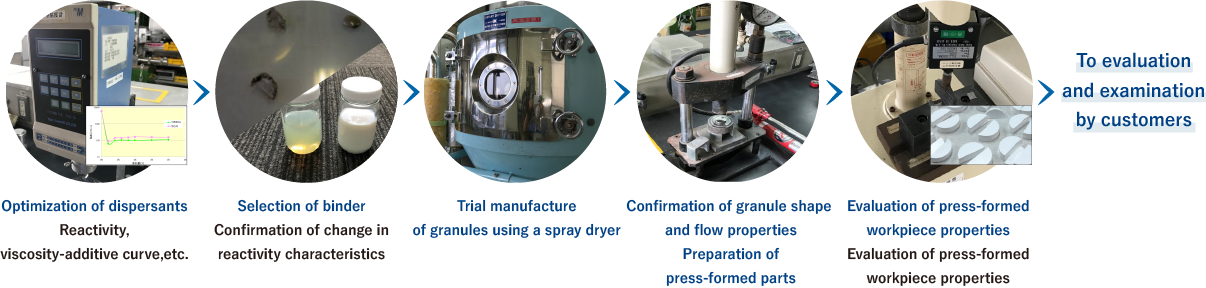

Dry press molding test process

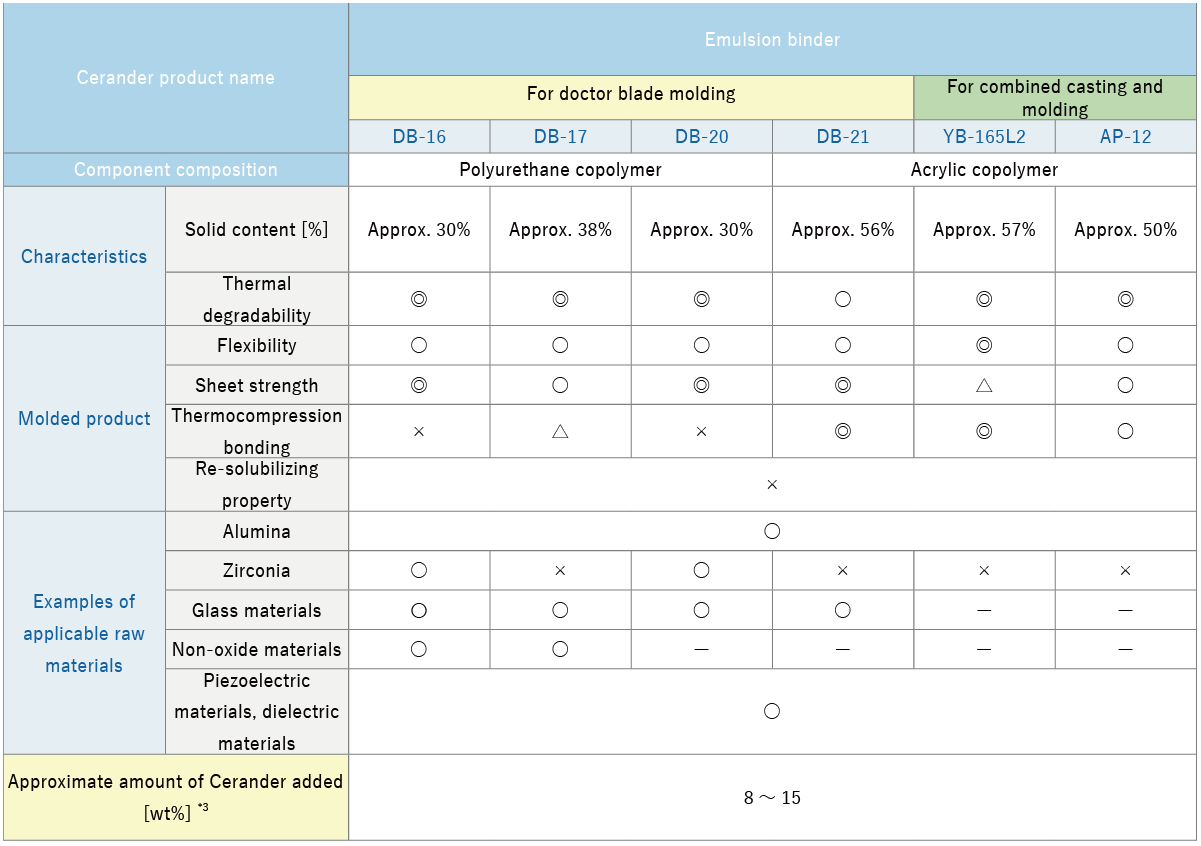

Binder for doctor blade molding

Since the binder for doctor blade molding is mainly composed of polyurethane copolymer, we offer a lineup of binders that make it easier to obtain molded products with higher production strength and density. We also offer binders that can be used for partial casting (YB-165L2, AP-12).

Product characteristics

* 3 The amount of Cerander added is the value in terms of solid content, which is the outer weight versus 100 parts by weight of the raw material powder.

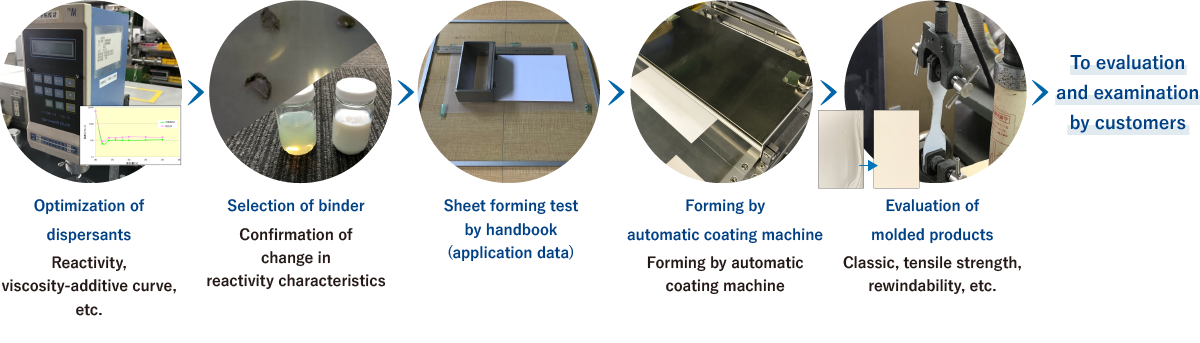

Doctor blade molding test process

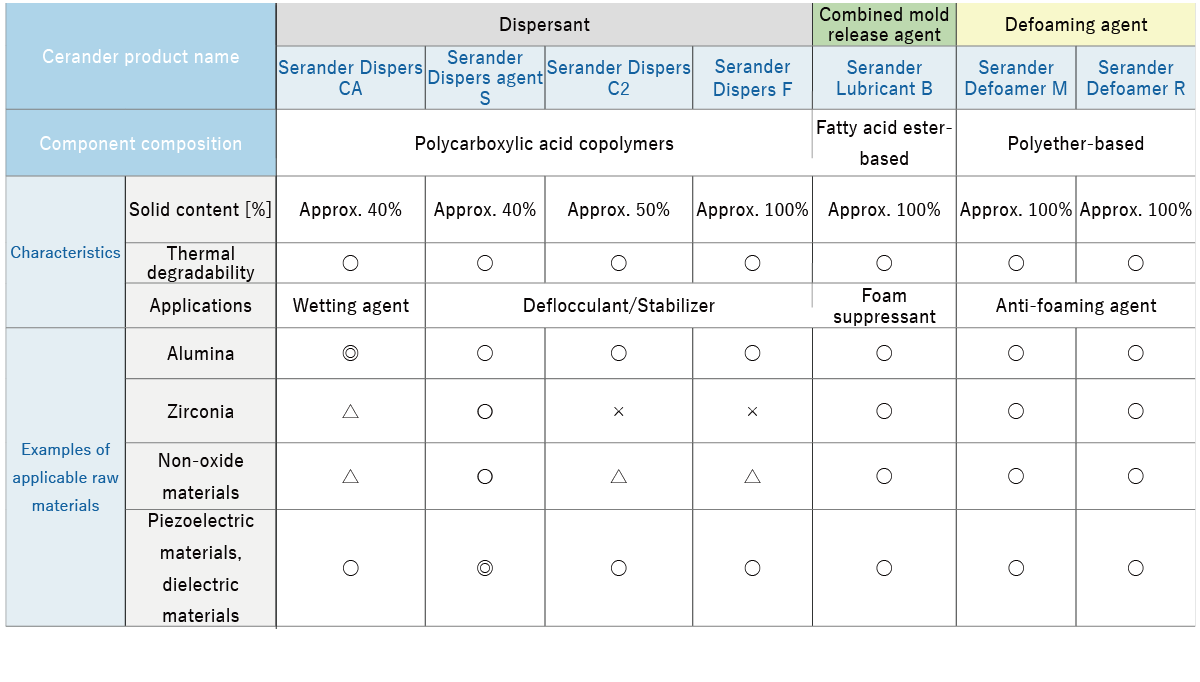

Other additives

Dispersant

First, please use dispersant S, which has a high moisturizing effect, for fine particles such as nanoparticles, and dispersant CA for general particle size dispersion, peptization, and stabilizers.

Defoamer

First, please use mold release agent B as a defoaming agent to improve foaming during mixing and kneading with a ball mill, etc., and defoamer M to improve defoaming properties during defoaming after a ball mill, etc.

Product characteristics

* 4 The amount of Serander added is the value in terms of solid content, which is the outer weight versus 100 parts by weight of the raw material powder.

Contact us

E-mail:pj-serander@highchem.co.jp